How to Ensure the Quality of High Purity Gases for Industrial and Medical Use

Introduction to High Purity Gases

High purity gases are essential components in both industrial and medical applications. Their quality directly impacts the efficiency and safety of operations, ranging from manufacturing processes to patient care. Ensuring the purity of these gases is crucial, as impurities can lead to significant problems, including product contamination and health risks.

Understanding Gas Purity Levels

The purity of gases is defined by the absence of impurities. In industrial applications, these gases are often used in processes that require stringent control over chemical reactions. In medical settings, high purity gases are vital for patient safety and treatment efficacy. The gas purity is typically measured in terms of percentage, with 99.999% being a common benchmark for high purity.

Methods for Measuring Gas Purity

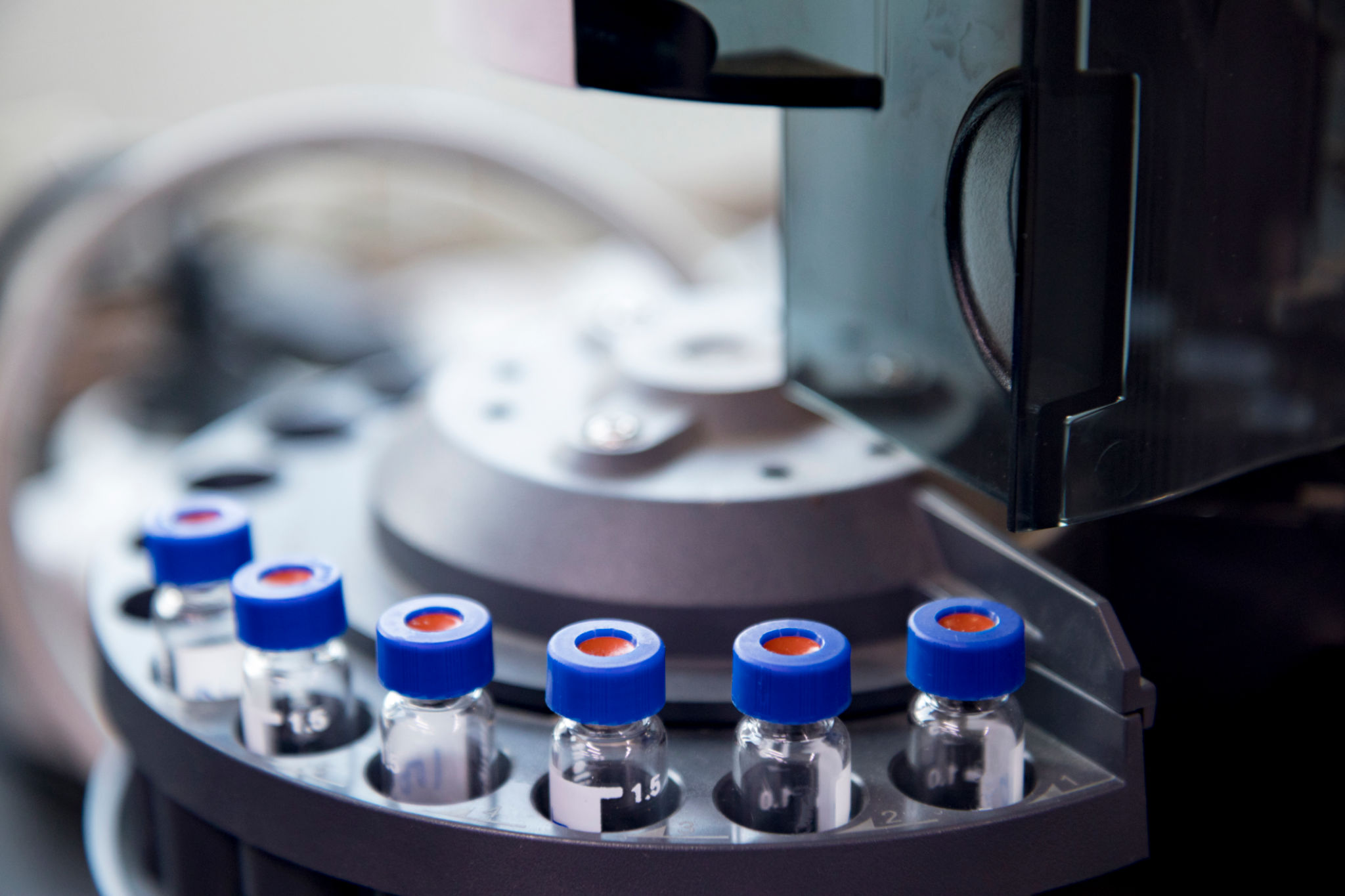

Several methods are available to measure the purity of gases. Gas chromatography is one of the most widely used techniques. It involves separating and analyzing components in a gas mixture to identify and quantify impurities. Other methods include mass spectrometry and infrared spectroscopy, each offering unique advantages depending on the application.

Ensuring Quality Control in Gas Production

Quality control in the production of high purity gases starts with sourcing raw materials that meet stringent standards. Producers must implement rigorous testing protocols at every stage of production to ensure consistency and compliance with industry regulations. Adhering to international standards such as ISO 9001 can further enhance quality assurance.

Role of Equipment and Technology

Advanced equipment and technology play a pivotal role in maintaining gas quality. Automated systems equipped with real-time monitoring capabilities help detect any deviations from set purity levels. Regular maintenance and calibration of equipment are equally important to prevent contamination and ensure accurate measurements.

Storage and Distribution Considerations

Once produced, high purity gases must be stored and distributed carefully to maintain their quality. Storage containers should be made of materials that do not react with the gases. Additionally, they must be designed to prevent leakage and contamination. Implementing a robust tracking system during distribution ensures that gas purity is maintained from production to end-use.

Training and Safety Protocols

Proper training for personnel handling high purity gases is essential. Workers should be well-versed in safety protocols and emergency procedures. Regular training sessions help reinforce best practices and keep staff updated on the latest industry standards and technologies.

Conclusion: Continuous Improvement

Ensuring the quality of high purity gases requires a comprehensive approach involving stringent quality control measures, advanced technology, and continuous education. By prioritizing these elements, industries can safeguard their processes and ensure that medical applications deliver optimal outcomes. The commitment to quality not only enhances operational efficiency but also fosters trust and reliability in the market.