Ensuring Quality: How to Verify High Purity Gases for Medical Use

The Importance of High Purity Gases in Medical Applications

Medical gases play a critical role in patient care, from anesthesia to respiratory therapy. Ensuring the purity of these gases is vital to patient safety and treatment efficacy. High purity gases are free from contaminants that could otherwise lead to adverse health effects or compromise medical procedures.

Understanding Gas Purity Standards

To ensure safety and effectiveness, medical gases must meet stringent purity standards set by regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA). These standards specify acceptable levels of impurities and dictate how gases should be produced, stored, and delivered. Adherence to these standards is not only a legal requirement but also a moral responsibility for healthcare providers.

The primary components assessed in purity standards include oxygen, nitrogen, carbon dioxide, and nitrous oxide. Each gas has specific requirements that determine its suitability for medical use. For instance, medical oxygen must have a purity of at least 99.5% to be deemed safe for therapeutic use.

Methods for Verifying Gas Purity

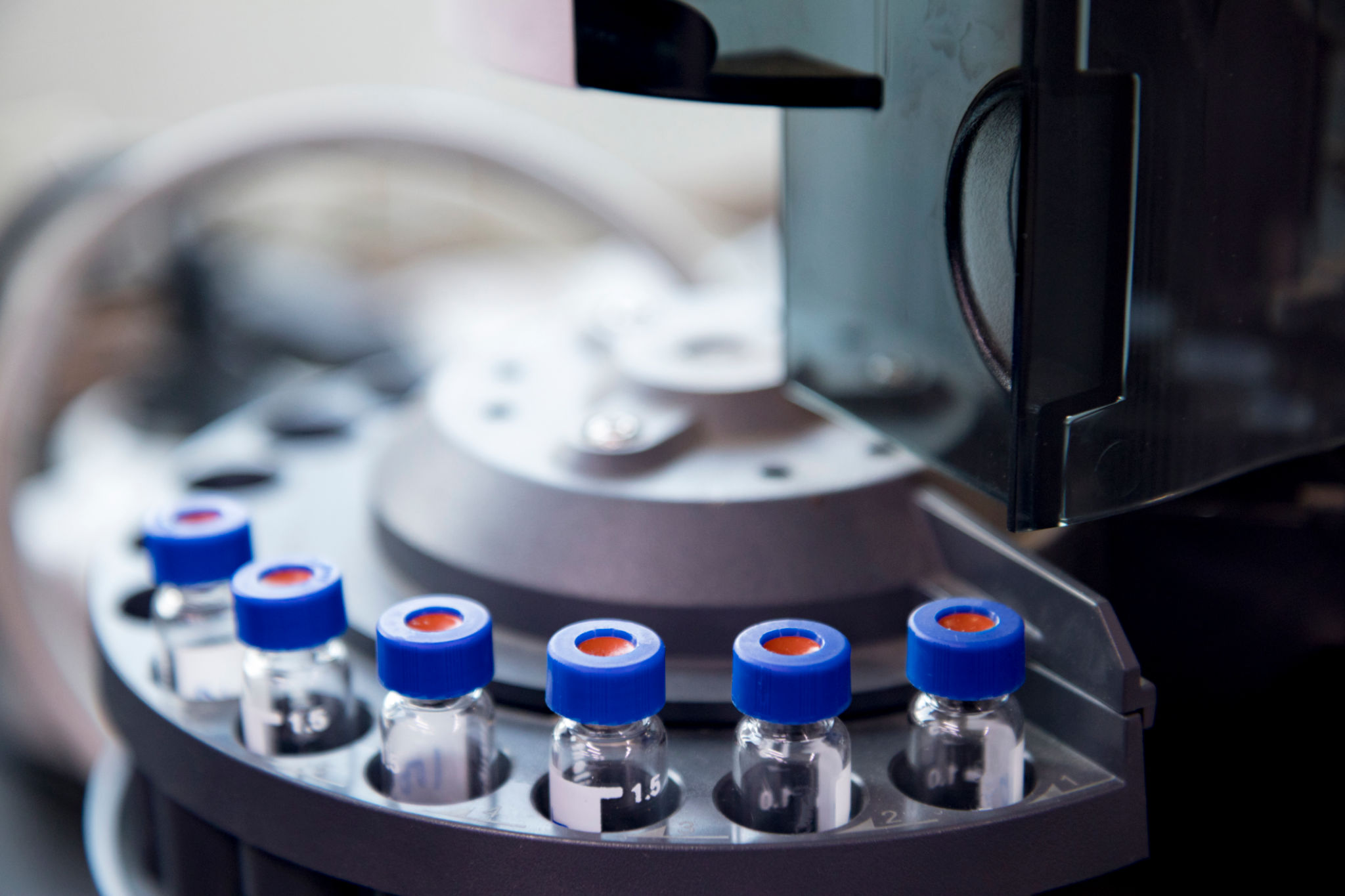

There are several methods employed to verify the purity of medical gases. One common approach is gas chromatography, which separates and analyzes the components within a gas mixture. This method is highly effective in detecting impurities at very low concentrations.

Additionally, infrared spectroscopy is used to identify molecular compositions by measuring the absorption of infrared light. This technique is particularly useful for detecting specific contaminants that may not be discernible through other methods. Regular testing using these advanced methods ensures that medical facilities consistently utilize high purity gases.

The Role of Certification and Documentation

Certification plays a crucial role in verifying gas purity. Suppliers of medical gases must provide documentation that certifies compliance with established standards. This documentation often includes batch numbers, test results, and expiration dates, ensuring traceability and accountability.

Healthcare facilities should maintain comprehensive records of all gases received and used. This practice not only facilitates quality assurance but also supports any necessary audits or investigations regarding patient safety.

Storage and Handling Practices

Proper storage and handling are essential to maintaining the purity of medical gases. Cylinders should be stored in a clean, dry environment away from potential contaminants. Facilities must also implement protocols for safe handling to prevent contamination during use.

Regular training for healthcare staff on handling practices can significantly reduce the risk of contamination. By emphasizing the importance of these protocols, facilities can ensure that every aspect of gas management contributes to maintaining high purity levels.

Conclusion: Commitment to Safety and Quality

Ensuring the purity of medical gases is a multifaceted process that requires adherence to rigorous standards, verification through advanced testing methods, and meticulous documentation. By committing to these practices, healthcare facilities can uphold the highest levels of patient safety and care quality.

The responsibility lies not only with gas suppliers but also with healthcare providers who must remain vigilant at every stage—from procurement to application—to protect patients and enhance treatment outcomes.